Institute for Competitiveness credits Ministry of Textiles for turning around the PPE Industry into a global exporter in a little over four months.

India can adopt strategies to transform into a global manufacturing hub for high quality PPE kits, says a report prepared by the Institute for Competitiveness that is the Indian knot in the gobal network of Institute for Strategy and Competitiveness at Harvard Business School. Giving an overview of India’s journey of achieving self-sufficiency in manufacturing high-quality PPE kits, the report credits the government’s “Go Local” initiative to turn the crisis of acute shortage into an opportunity to develop an indigenous supply chain for manufacturing class-3 PPEs and testing swabs.

The Ministry of Textiles led this initiative and set up the end to end value chain for manufacturing of PPE kits within a time-span of one to two months. The report details the role of each stakeholder involved and also recommends strategies to adopt for the future with a view to transform India into a global manufacturing hub.

According to the report, moving forwards, India needs to enable strong quality assurance (QA) and quality control (QC) processes among all the PPE manufacturers. It will bring more consistency into the quality of the PPEs manufactured, reduce the testing and rejection overheads post-delivery and allow local manufacturers to scale up their production to reach not only domestic markets but also global markets.

According to Amit Kapoor, Chair, Institute of Competitiveness, “We need to shift our mindsets from focusing on cost to ensuring world-class quality, if we, as a nation want to be known as high-quality manufacturer with economical costing rather than a cheap quality nation with low costing.”

The report points out that even though India achieved self-sufficiency in terms of localized manufacturers and production of PPE body coveralls, PPE fabric and seam tapes, it still relied on imports for procuring a critical component like seam sealing equipment. In order to have complete control over the end-to-end manufacturing value chain for essential medical supplies and to become a fully capable manufacturer of highest quality PPE kits and other essential medical supplies, India needs to indigenize the production of critical equipment and machineries for essential medical supplies as well, the report says.

“There is still more room for improvement in the quality of locally-manufactured PPE kits. Hence, India need to step up the R&D efforts to improve the quality further. It will also enhance the competitiveness of the indigenous PPE industry in the global market in the near future,” says Kapoor.

The Ministry of Textiles had launched “Operation PPE Coverall” in late March 2020 to scale up the initiative.The South India Textile Research Association (SITRA) spearheaded the testing programme for PPE kits during the pilot run in Mar-Apr 2020. Later, seven more government entities were approved as testing and certification labs for PPE Body Coveralls. These labs were strategically selected across different parts of India to ensure efficient testing of PPE kits across the country and to reduce the post-production timeframe involved in testing, clearance, and dispatch of the PPE kits.

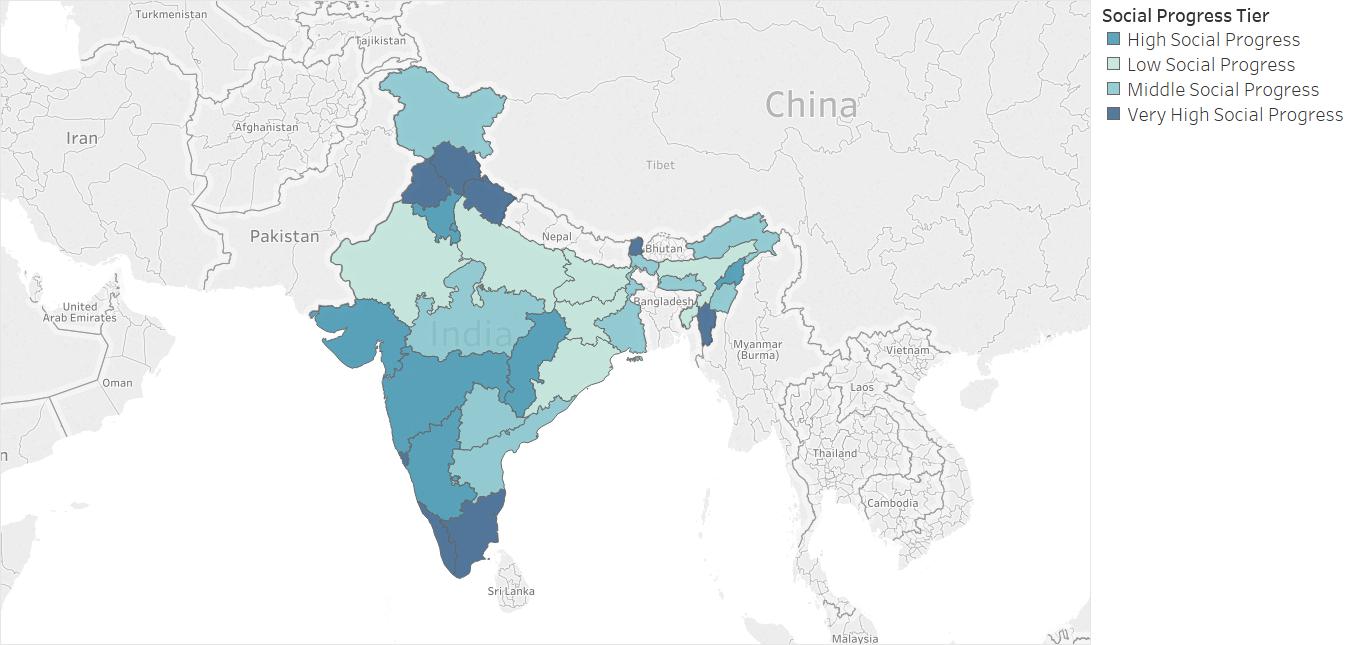

According to the report, a cluster-based approach was adopted to develop the local capabilities for manufacturing PPE kits. The Ministry of Textiles facilitated the development of PPE manufacturers in small and medium clusters across different parts of India to speed up the process By May, India had developed an indigenous network of PPE fabric and garment manufacturers having the necessary processes, capability and capacity of manufacturing 4.5 lakhs pieces of body coveralls and N-95 masks per day. By July, India’s indigenous supply of PPE kits had exceeded the domestic demand and it exported 23,00,000 personal protection equipment (PPE) to the US, the UK, Senegal, Slovenia, and UAE. India was thus able to transform from an importer country to a self-sufficient one and later an exporter country in PPE kits.